Making money with CNC Plaster is indeed very much possible, but it’s not an easy cakewalk. You will need to buy the equipment, software, skill, design ideas, and a bit of luck to start making money.

Having used my friend’s CNC plasma cutter for over five years here and there, I can attest to its capabilities and the various projects it has allowed me to take on.

How to Make Money with a Plasma Cutter?

To Make Money with a CNC Plasma Cutter: Provide Custom Metal Fabrication, Sell Artistic Metalwork, Custom Signage, Industrial Cutting Services, Metal Restoration, Automotive Customization, Home Improvement Products, Metal Jewelry and Accessories, Prototyping Services, Artistic Sculptures.

There are so many opportunities to make money with a plasma cutter! I’ve been using mine for years and have found some great opportunities to turn my hobby into a profitable business.

Here are some ways you can also make money with your plasma cutter:

1. Custom Metal Fabrication

If you already have experience with metalworking, a Plasma cutter is the best option for you as you can create precise metal parts, components, or structures for clients while getting paid decently.

These could be anything from brackets and panels to decorative items.

2. Artistic Metalwork

Let’s say you are the creative one, then you can use your plasma cutter to create unique metal art pieces, sculptures, or decorative items.

Sell your artwork at art fairs, online marketplaces, or to interior designers.

3. Custom Signage

Craft custom metal signs for businesses, events, or individuals and cut out letters, logos, or intricate designs to make eye-catching signage.

4. Industrial Cutting Services

You can promote yourself and offer clients industrial cutting services to manufacturing and construction companies.

Advertise yourself that you can Precisely cut metal sheets, pipes, or beams based on their specifications.

This is a great way to level up and use your plasma cutter for small bracelets to larger projects and make some serious money.

5. Metal Restoration

I love antiques and if you are like me, restoring antique metal items sounds fun.

Restored pieces can be sold to collectors or enthusiasts.

6. Automotive Customization

How about you create Exhaust tips, grilles, or decorative features for unique items vehicles?

7. Home Improvement Products

My wife loves to shop for antiques and rusty decor. You can create gates, railings, or fireplace screens.

Market them to homeowners looking for customized, quality solutions.

8. Metal Jewelry and Accessories

I think and know that Crafting metal jewelry items such as earrings, pendants, or cufflinks can be such a profitable gig as they usually sell in numbers.

People love jewelry and they are not that expensive unless you add a diamond to it, they can be pretty affordable.

Sell your creations at craft fairs, online stores, or through jewelry retailers.

9. Prototyping Services

Offering prototyping services to inventors, product developers, or entrepreneurs sounds fun right?

Well, Use your plasma cutter to create prototypes of their designs and showcase them.

10. Artistic Sculptures

Create artistic metal sculptures for decorative or functional purposes that can be sold to art galleries, collectors, or public installations.

11. Custom Furniture

If you love to Design and build custom metal furniture pieces like tables, chairs, or shelving units, give it a try.

12. Repair and Modification Services

Let’s say repair and modification services for metal objects, such as fixing damaged parts or modifying existing structures are your thing.

This is a great way to use your skills to help others and make some money in the process.

13. DIY Workshops and Classes

If you are experienced and have some knowledge that will provide insights and value to others, host workshops or classes to teach others how to use a plasma cutter.

Use words like these to sell your classes: In my years of operating a CNC plasma cutter, I’ve worked on diverse projects, from crafting custom signs for local businesses to fabricating intricate metal art pieces for art exhibitions. Learn insider tips from me and join today.

14. Online Tutorials and Content Creation

Create instructional videos or write tutorials about plasma-cutting techniques.

You can monetize your content through platforms like YouTube or your website.

15. Custom Metal Gifts

People love custom things, custom cars, custom designs, and custom shoes. So, why not custom metal gufts?

Offer personalized metal gifts for special occasions like weddings or anniversaries via custom-engraved items or decorative pieces.

The Cost involved in CNC plasma tables

I have factored in the size of the table, the type of plasma cutter used, and the software required to operate the machine for the overall cost.

- CNC plasma table: $5000-$100,000. For example, a 4×4 table can cost around $5,000, while a 4×8 table can cost upwards of $10,000.

- Plasma cutter: $1,500 to $10,000 or more.

- Software required: $400 – $10000

Your bank balance can quite hurt lol

CNC Plasma Table Equipment: Complete List

Let me break it down for you:

1. Plasma Table

The plasma table is the centerpiece of your metal fabrication operation.

Basically, It’s a computer-controlled cutting machine that uses a plasma torch to cut through metal.

2. Plasma Cutter

It is a handheld tool that uses a plasma torch to cut through metal and make precise cuts on your metal pieces, both before and after they go through the plasma table.

3. CAD Software

To design your metal pieces, you’ll need computer-aided design (CAD) software.

This software allows you to create precise 2D and 3D models of your metal pieces, which you can then import into your plasma table’s control software.

4. CNC Software

After you’ve designed your metal pieces, computer numerical control (CNC) software controls your plasma table and designs you’ve created in CAD software.

It translates them into cutting instructions for your plasma table.

How to Install Your CNC Plasma Cutter?

Once you have chosen your plaster, it’s time for the installation.

As someone who has installed a few of these machines, let me tell you, it’s not as complicated as you might think.

Step 1: Choose the Right location

Before you start installing your CNC plasma cutter, you need to choose the right location for it.

Ideally, you want to place it in a dry, well-ventilated area that’s not too close to other machines or equipment.

You also want to make sure you have enough space to move around the machine and access all of its components.

Step 2: Prepare the workspace

This basically means that you need to clear out any clutter, remove any obstacles, and ensure the area is clean and free of debris.

Check the tools and equipment on hand, such as a level, a tape measure, and a set of wrenches.

Step 3: Assemble the machine

It can sound intimidating but it’s quite simple:

- Attach the frame, the torch bracket, and the Z-axis (up and down) to the machine.

- Next, install the plasma power equipment to manipulate and move the plasma torch to produce the required cutting parts.

Step 4: Connect the Electrical Components

Wire up the plasma power supply, the motor controllers, and the limit switches.

I want you to connect the machine to a power source and test the electrical connections to make sure everything is working correctly. This is important as it is necessary that there is no hindrance in the power supply or the installation process.

The Electricity Bills alone will be scary.

Step 5: Configure the software

Now, you can finally install the CNC software, set up the machine parameters, and calibrate the machine.

Once that is done, test the machine to make sure it’s cutting accurately and efficiently.

How to Operate a CNC Plasma Table?

It can sound complicated, but I will guide you through the process:

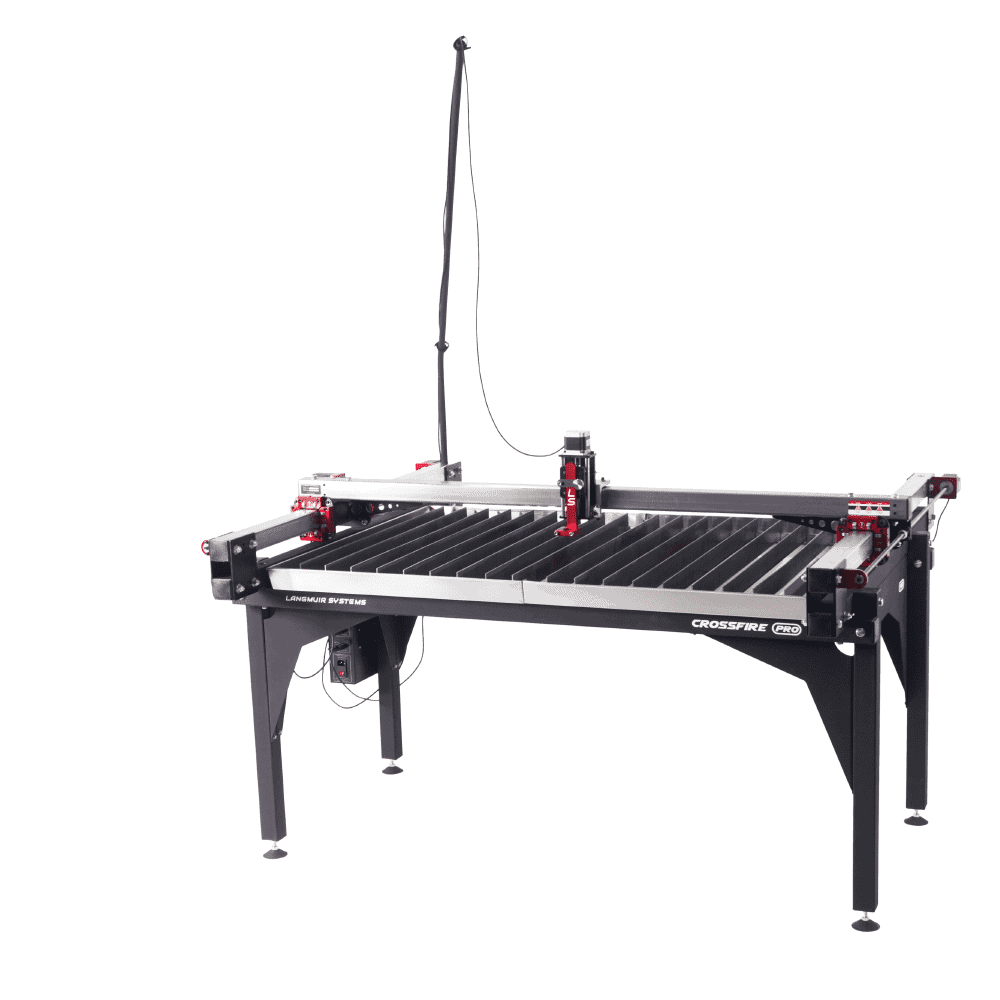

Step 1: Selecting a CNC Plasma Table

Choose a suitable CNC plasma table for your needs and consider other factors like table size, cutting capabilities, and your budget.

I personally recommend the Langmuir Systems Crossfire Pro.

Step 2: Setting Up the Equipment

- Plug in the plasma table controller to a standard 120V receptacle.

- Next, Connect the plasma cutter, which typically requires a 30A 240V power source.

- Ensure your plasma table has an air supply, and connect it.

- Turn on the plasma cutter and the plasma table controller.

Step 3: Preparing the Workpiece

- Place the steel sheet on the plasma table, ensuring it fits within the table’s dimensions.

- Attach a grounding clamp to the workpiece. Clean the surface for a solid connection.

- Check the CAD design and make sure it’s ready for cutting.

Step 4: CAD Design and Software Setup

- Find an image or design you want to cut and upload it into CAD software like Fusion 360.

- Trace the image using CAD tools, creating a cut path.

- Export the design to the control software (e.g., Fire Control) used by your plasma table.

- Configure the cut parameters, such as cut rates and lead-in distances.

Step 5: Zero Axis Setup

- Position the plasma torch head at the desired starting point on the workpiece (typically the bottom-left corner).

- Zero all axes in the control software, ensuring the machine knows its reference point.

Step 6: CNC Plasma Cutting

- Initiate the cutting process through the control software.

- The machine will follow the programmed cut path, executing the design on the workpiece.

- Monitor the cutting process for any issues.

Step 7: Post-Cutting Cleanup

- After cutting, clean the workpiece’s backside to remove any slag or imperfections using appropriate tools.

- Finish the workpiece as needed, which may include painting or clear coating.

One of the most rewarding experiences I’ve had with my CNC plasma cutter was when I created a personalized metal sign for a family celebrating their anniversary. It felt great to contribute to their special day.

Choosing the Right CNC Plasma Cutter

Like all things, choosing the right machine is crucial and you need to consider a few factors before making a purchase:

1. Size

The size of the CNC plasma cutter you choose will depend on the size of the materials you plan to cut.

Let’s say, you plan to work with large sheets of metal, you’ll need a machine with a larger cutting area and a smaller machine for smaller pieces.

So, what you want to create is important when choosing the machine.

2. Power Requirements

Another important factor is how much power it consumes. You need to make sure that the machine you choose is compatible with the power supply in your workspace, not much or less.

If the power it consumes is too weak, it might not have enough power to cut through the materials you plan to work with.

That is why you need to match the power.

3. Software Compatibility

Finally, the most important is to consider the software compatibility of the CNC plasma cutter you choose.

This is crucial as it controls the design and the cutting process and will determine the accuracy and precision of the cuts.

How Much Air Pressure Does a Plasma Cutter Need?

| Plasma Cutter Type | Amperage Range | Air Pressure Requirement |

|---|---|---|

| Small Handheld Plasma Cutter | 20-30 amps | Typically 80 psi (5.5 bar) |

| Larger Automated Plasma Cutter | 130-800 amps | Around 115 psi (8 bar) or more |

What Factors Should Be Considered When Choosing a CNC Plasma Table?

- Budget: CNC machines can cost anywhere from $20,000 to over $100,000, depending on the size and features you need.

- Size of the table: It Should be large enough to accommodate the size of the materials you will be cutting.

- Cutting speed: It is determined by the power of the plasma cutter and the speed of the table. A higher cutting speed will allow you to complete projects faster.

- Durability and construction: Choose a table that is built to last and can withstand the wear and tear of daily use.

- Software compatibility: You can easily transfer your designs to the table and start cutting.

- Additional features: Height control, advanced software features, complex designs, etc

Why Having a Clear Plan for Utilizing a CNC Plasma Table is Essential

I know someone who has worked with CNC plasma cutters for years and I can tell you that investing in a CNC plasma table without a clear plan for how you will use it is a recipe for disaster.

Before making the investment, I urge you to have a clear plan for how you will utilize the machine.

Without a plan, you may end up using the machine inefficiently, which can lead to wasted time, materials, and money.

To avoid these issues, take the time to develop a clear plan for how you will use your CNC plasma table.

- Details on the types of projects you will take on

- Materials you will work with

- Equipment and training you will need.

How Can You Make Signage Created with a CNC Plasma Table Stand Out in a Competitive Market?

It can be such a daunting task to make your signs stand out in a crowded market. But it is not impossible and here are some tips to help you achieve:

- Use unique designs that are not commonly seen in the market. (create custom designs that reflect your client’s brand or message.)

- Try different materials such as stainless steel, copper, or aluminum instead of the standard mild steel.

- Add color to your signs to make it more attractive and eye-catching. I personally use powder coating services to produce vivid colors for your designs.

What Can You Create with a CNC Plasma Table?

Oh, I can think of a few things on top of my head.

| Designs | Description |

|---|---|

| Custom Metal Art | Imagine this: you can create one-of-a-kind metal art pieces with fancy designs such as Craft wall art, sculptures, and cool signage, all personalized for that extra special touch. |

| Getting into Metal Fabrication | Cut metal into precise shapes for various projects – think railings, gates, and fences. |

| Becoming a Sign-Making Pro | Become the go-to person for custom signs, whether for businesses or homes, and add your artistic touch with paint or finishes |

| Mastering Metal Restoration | Restore old and worn-out metal items, like classic car parts or antique treasures. |

| Offering Industrial Cutting | Become the go-to person for custom signs, whether for businesses or homes and add your artistic touch with paint or finishes |

| Crafting and Selling Metal Signage | Craft custom metal signs and add logos and names through engraving – people will absolutely love the personal touch! |

| Designing and Selling Metal Jewelry | For the fashion-forward crowd, why not create and sell your own metal jewelry? From earrings to bracelets, there’s a growing market for handmade metal bling. |

| Creating Artistic Metal Sculptures | Art galleries, museums, and even individual art enthusiasts will appreciate and adore your unique creations. |

How Can CNC Plasma Cutting Be Turned into a Profitable Venture for Car or Motorcycle Enthusiasts?

If you are like me and love cars, you can turn this passion into a profitable venture by creating custom parts and accessories.

- Create custom parts for classic cars and motorcycles.

- You can also create custom parts for race cars and motorcycles. Racing enthusiasts are always looking for ways to improve the performance of their vehicles.

- Offer CNC plasma cutting services to others who want to create their own custom parts.

What marketing strategies worked for me to promote my CNC plasma table business effectively?

We all know that starting a CNC plasma-cutting business is a great way to earn money, but it’s not enough to have the best equipment and skills.

You also need to market your business effectively to attract customers. (if others don’t know about it, how will they buy)

- Online Presence: Create a website and social media accounts. Regularly update and showcase your work.

- Networking: Build relationships with potential customers and other businesses by attending trade shows, conferences, and local events to meet people and promote your business.

- Offering Discounts: Offering discounts or special promotions.

- Targeted Advertising: I use Google Ads and Facebook Ads to target specific demographics and interests.

What is the Income Potential of a CNC Plasma Table?

It’s quite high but the more time and effort you put in, the higher the potential for income.

The income potential of a CNC plasma table can vary widely based on several factors, including location, skill level, specialization, and the type of projects undertaken.

In the USA, the average salary for CNC plasma operators is approximately $37,440 per year or $18 per hour.

Entry-level positions may start at around $32,175 per year, while experienced workers can earn up to $47,840 per year.

Based on my years of experience using a CNC plasma cutter, I can confidently recommend it is a viable business model but it requires some work like all work and business existing today.

CNC Plasma Expense: How Much Do You Expect to Spend?

Just like any business, there are expenses that come with it.

- Material expenses: Depending on the type of material you’re cutting, you can expect to spend anywhere from $400 to $1500 per month on materials alone.

- Plasma consumables: My rough estimate is around $150 per month. Basically, these are recurring expenses and they are the parts that wear out over time and need to be replaced such as nozzles, electrodes, and shields.

- Finishing costs: $40-$80 and they include Sanding, painting, or powder coating.

Now, I want to talk about the good stuff, gross revenue. On average, a CNC plasma-cutting business can bring in around $3000 per month in gross revenue. But that number can change at all times and fluctuate.

So, what does this all mean for your bottom line?

Well, after factoring in your expenses, you can expect to net anywhere from $900 to $2000 per month.

Skills Required

- Metal Fabrication

- CAD Design

- CNC Programming

- Creative Problem-Solving

In my experience, I’ve found that using a CNC plasma cutter requires attention to detail and precision.

I’ve also discovered that creativity knows no bounds when it comes to crafting metal art.

Frequently Asked Questions

What are some profitable items to make with a CNC plasma cutter?

Custom metal signs, wall art, furniture, automotive parts, and even jewelry.

What are the start-up costs for a CNC plasma-cutting business?

A basic CNC plasma cutting table can cost anywhere from $5,000 to $10,000, while a larger industrial-grade machine can cost upwards of $100,000. You’ll also need to factor in the cost of materials, software, and marketing.

What safety precautions should I take when using a CNC plasma cutter?

Wear protective clothing, such as gloves and eye goggles, and ensure that your work area is well-ventilated to avoid inhaling toxic fumes.

What is a CNC Plasma Cutter?

CNC stands for Computer Numerical Control which is used to cut very precise and allows intricate designing. It uses a plasma torch to cut through metal and creates a high-temperature plasma arc that melts the metal and blows it away from the cut.